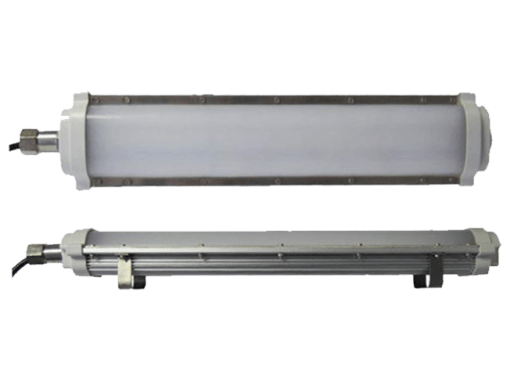

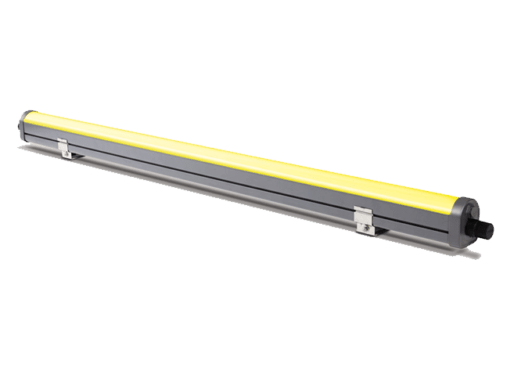

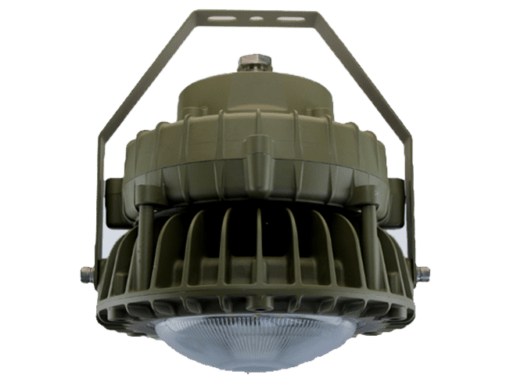

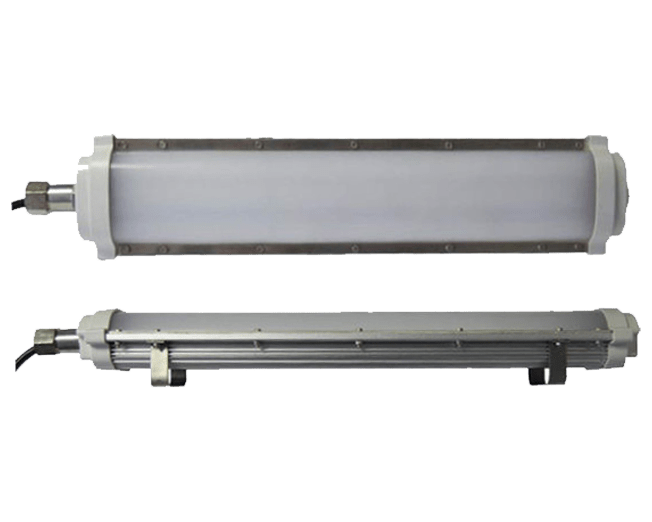

Explosion Proof Tube Light

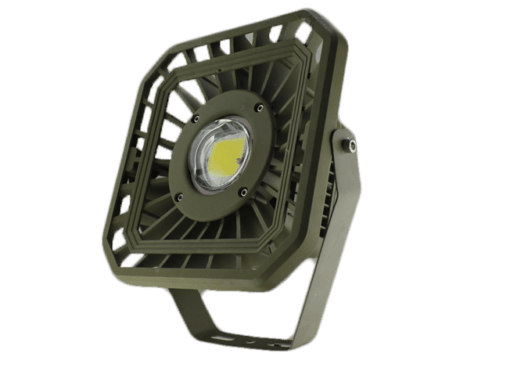

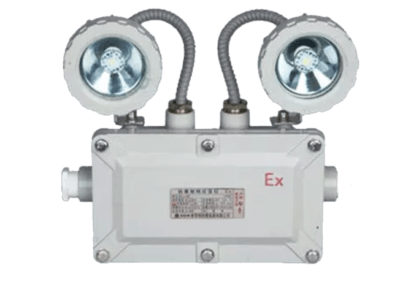

Explosion-proof lighting refers to lighting fixtures that are specifically designed and constructed to prevent the ignition of flammable gases, vapors, liquids, or combustible dust in hazardous environments. These environments may include areas where there is a risk of explosion due to the presence of volatile substances such as gases or dust particles. Explosion-proof lighting is crucial in industries such as petrochemical, oil and gas, mining, chemical processing, and manufacturing where the potential for explosive atmospheres exists.

Explosion Proof Tube Light

The salient features of explosion-proof lighting encompass a meticulously designed enclosed structure, robust enough to confine any potential sparks or heat generated by the light within the fixture, thus averting the ignition of surrounding flammable substances. These fixtures boast a tightly sealed construction to thwart the entry of gases or dust, mitigating the risk of ignition in the presence of electrical equipment.

Explosion Proof Tube Light

Explosion-proof tube lights are a type of lighting fixture that are specifically designed to prevent explosions and fires in hazardous environments, such as oil refineries, chemical plants, and other industrial facilities. They are certified to meet strict safety standards, such as ATEX and IECEx, which are designed to protect against explosions in potentially explosive atmospheres. Explosion proof tube lights are constructed with a durable and rugged housing that can protect the internal components from dust, moisture, and other external factors. They are also designed to be IP65 rated, which means they are completely protected from dust and low-pressure water jets from any direction. The LED tubes used in explosion proof lights are typically encased in a heat-dissipating housing, which helps to ensure a long lifespan for the lights. They also come with built-in drivers that are designed to convert AC power to DC power, which is required by the LED tubes. Crafted from durable and corrosion-resistant materials, explosion-proof lights endure the rigors of harsh environmental conditions. Some designs incorporate cooling mechanisms, ensuring that the temperature within the fixture remains within safe limits, thereby minimizing the risk of ignition.

Safety Standard

Rigorous adherence to safety standards and certifications, such as those established by organizations like Underwriters Laboratories (UL) or the International Electrotechnical Commission (IEC), distinguishes explosion-proof lighting fixtures. ATEX or “Atmosphères Explosibles,” which is French for explosive atmospheres. It refers to a set of European Union (EU) directives and standards that regulate equipment and protective systems intended for use in potentially explosive atmospheres. The ATEX directives are crucial in ensuring the safety of workers and preventing explosions in environments where flammable gases, vapors, liquids, or combustible dust may be present.

Cost Effective

Ultimately, the overarching goal of explosion-proof lighting is to augment safety in environments prone to explosion hazards. By diligently preventing the ignition of volatile substances, these lights assume a pivotal role in averting accidents and safeguarding both personnel and assets in hazardous locations, embodying a crucial component of comprehensive safety protocols in high-risk industries. Explosion proof tube lights are a cost-effective and energy-efficient lighting solution that can provide long-term savings and improved lighting performance in hazardous environments, while ensuring the safety of the workers and the facility.

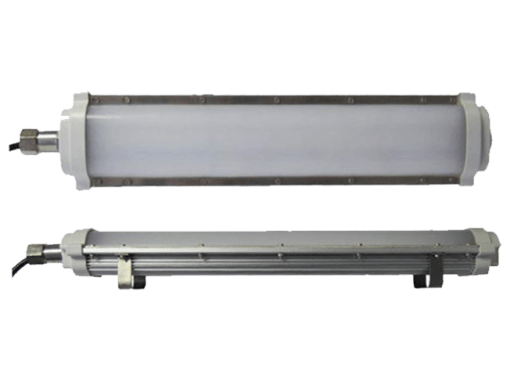

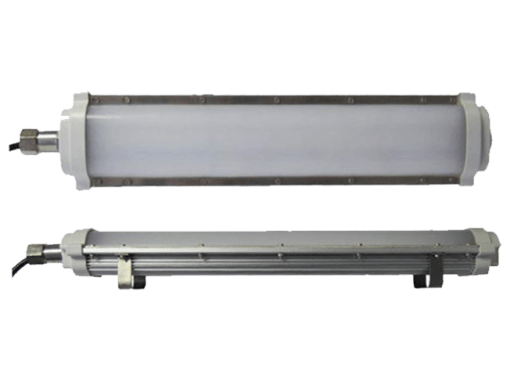

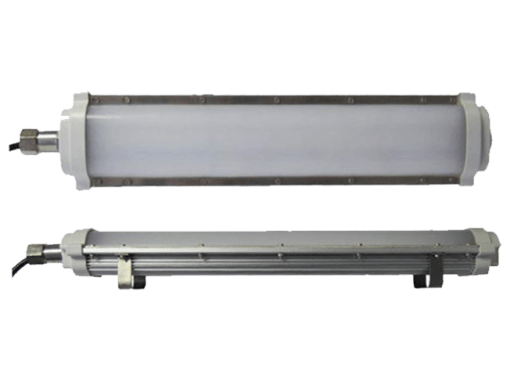

Explosion-Proof Tube Light

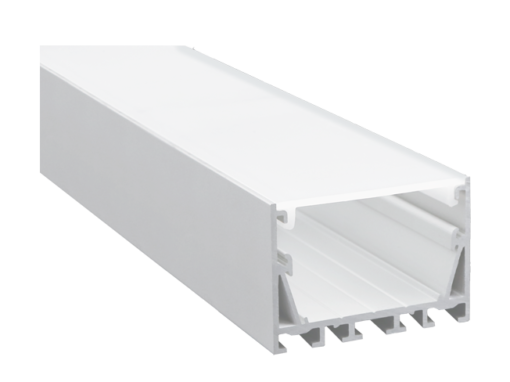

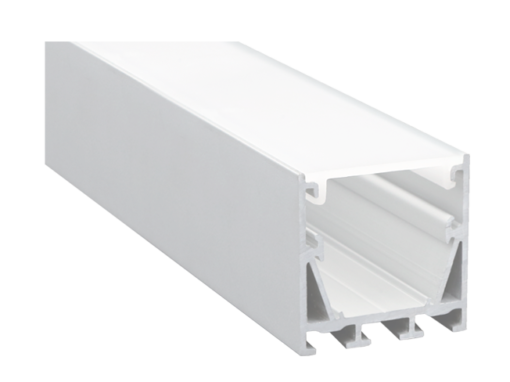

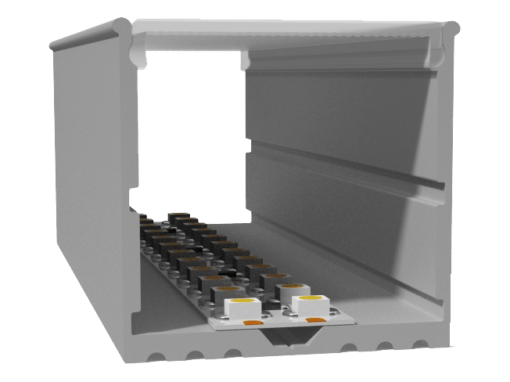

LED Tube Light – EX-LTL-A-Series

Power: 20W, 40W, 60W

LED Chip: Bridgelux

Life Span: 40,000 hrs

Lumens: 100lm/w

Input Voltage: 105-240VAC

Frequency: 50Hz / 60Hz

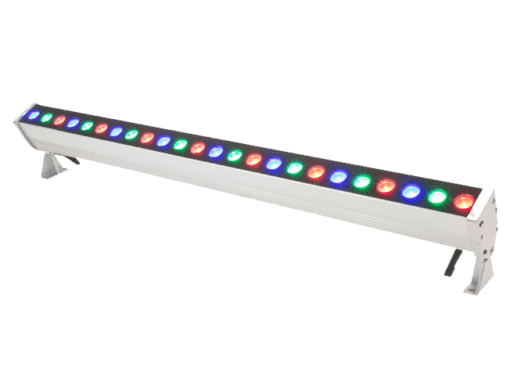

Light Color: Warm White/Daylight

CCT: 3000K/6500K

IP Grade: IP65 Outdoor

Anti Corrosion Grade: WF2

Power Factor: >0.98

Beam Angle: 120°

Material: Aluminium Base + High Quality PC

Storage Temperature: -40℃ to +60℃

Product Size (mm):

20W: L708XW132XH90.5mm

40W: L1315XW132XH90.5mm

60W: L1315XW132XH90.5mm

Explosion Mark: 2 G D Ex ec IIC T6 Gb, Ex tc IIC T80℃ Dc

Impact Resistant, Hot resistant

Corrosion Resistant Waterproof

Dust Proof, Corrosion-Resistant

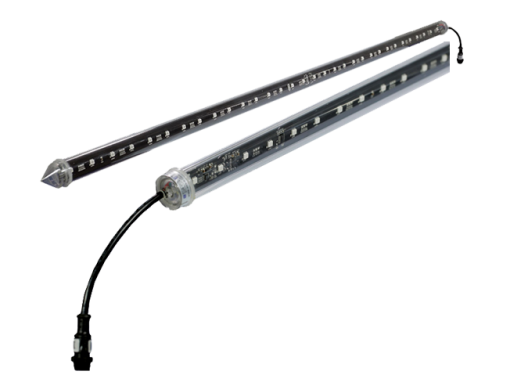

Explosion Proof Tube Light

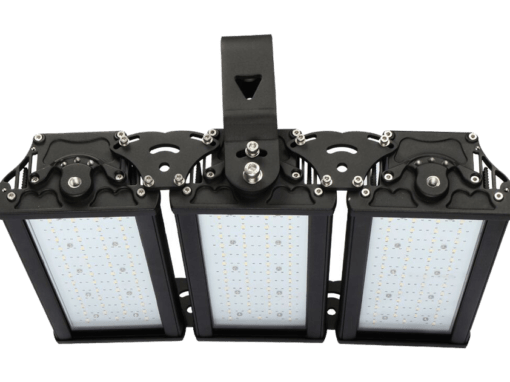

Explosion-proof tube lights find widespread use across diverse applications, owing to their specialized design that ensures safety and functionality in hazardous environments. Primarily employed in hazardous areas like oil refineries, chemical plants, and various industrial facilities, these tube lights are specifically engineered to mitigate the risk of explosions or fires, making them an indispensable safety measure in such environments. In mining operations, where harsh conditions and vibrations are prevalent, explosion-proof tube lights prove to be durable lighting solutions capable of withstanding the demanding nature of the industry.

Marine environments, including offshore oil rigs and ships, benefit from the deployment of explosion-proof tube lights. These lighting fixtures are crafted to resist dust, moisture, and other external factors, ensuring reliable illumination in challenging conditions. Similarly, in pharmaceutical facilities where maintaining a sterile environment is critical, explosion-proof tube lights offer protection against dust and moisture, meeting the stringent requirements of the industry.

Another noteworthy application is in storage tanks and silos, where explosion-proof tube lights play a crucial role in providing illumination while safeguarding against potential hazards. These fixtures are adept at withstanding external factors, ensuring consistent lighting in spaces where ordinary LED tube lights might be deemed unsuitable due to the hazardous nature of the environment.

In essence, explosion-proof tube lights stand out as versatile lighting solutions, offering durability and resilience in environments where standard LED tube lights would be inadequate. Beyond their robust construction, these lights contribute to energy efficiency while prioritizing the safety of both workers and the facility. Their suitability for diverse industries underscores their importance as an integral component in ensuring secure and effective lighting solutions in challenging and potentially dangerous work environments.

LOOK NO FURTHER

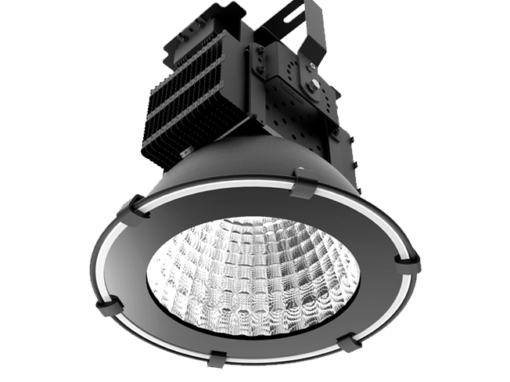

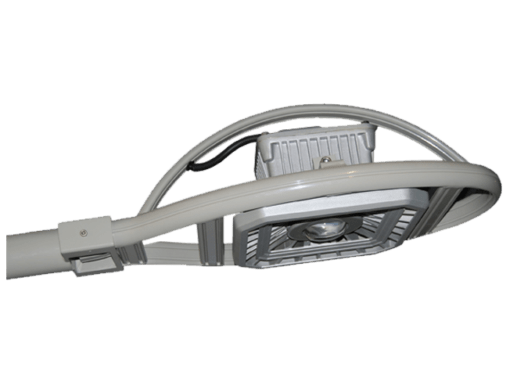

EXPLOSION-PROOF LED

LED LIGHTS